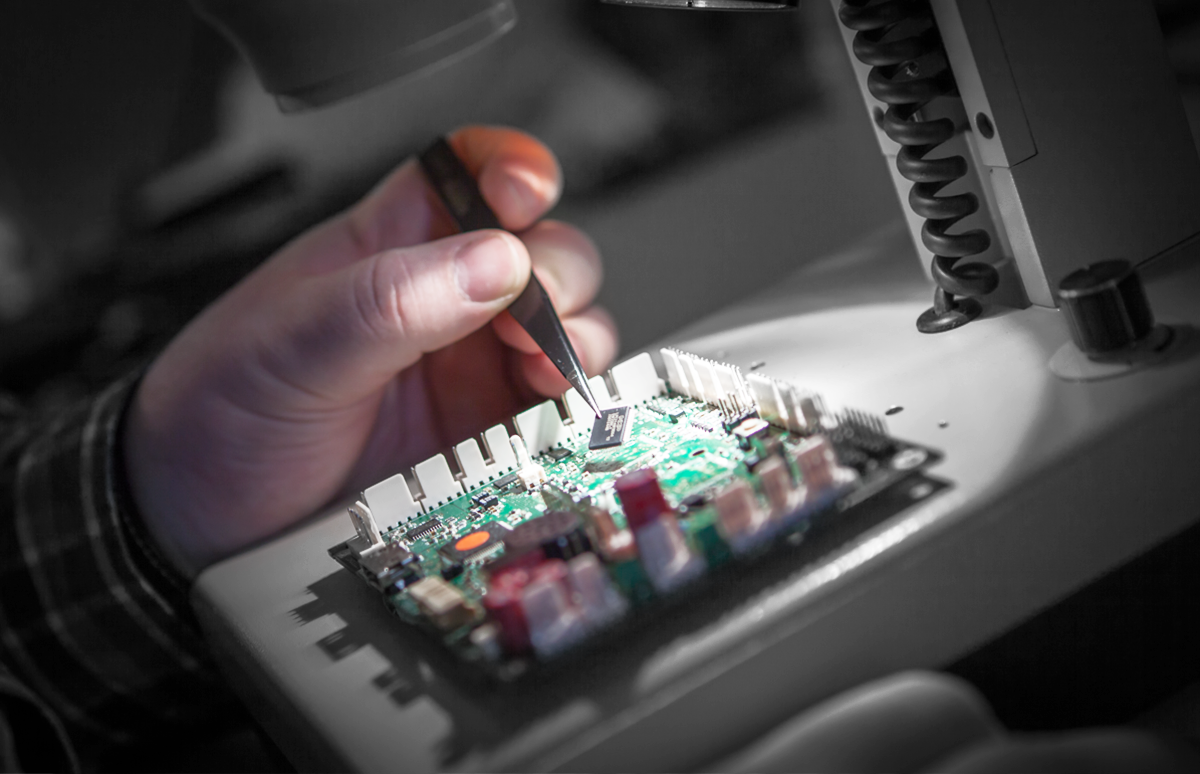

Hardness Test Technologies

You can use various hardness test technologies in the market to ascertain the hardness of any material that you want to work with in your production plant. These technologies are supported by state-of-the-art software solutions and equipment to ensure that the process is fast, effective and easy. The four popular methods include the following:

• Vickers: This method is also known as the microhardness test method. A diamond indenter punches a pyramid hole onto the surface. The technology has the widest scales for hardness tests and can be used on all metals.

• Rockwell: This test measures the depth of indentation produced by an indenter of known force. It is one of the easiest test methods, easy and requires the least amount of sample.

• Brinell: This is the oldest testing method and is commonly used to check the hardness of forgings and castings that are too coarse for Rockwell testing.

• Knoop: This test is used to measure hardness in very thin materials and uses forces lower than 500 gf. It can also show the variation of hardness in materials over very short distances.

Choosing the Right Hardness Test

The choice of each hardness technology depends on the material under test. In an industrial setting, you may invest in various technologies to check different materials. You should also take a keen look at the test load in terms of the force, and the hardness range of the indenter. Finally, pick hardware that can be adapted to accommodate materials of different sizes and shape. This helps lower the material preparation duration.